AKVA Group has confirmed the smolt recirculating aquaculture system (RAS) it delivered to Laxey has been in steady operation for some time, and that the Icelandic land-based salmon farmer received its third batch of eggs in July this year.

Fish from the two previous batches are filling up space in two of three RAS systems commissioned.

The collaboration between Laxey and AKVA began in 2022 with a contract to build Iceland’s first true RAS facility for Atlantic salmon smolt in Vestmannaeyjar. This facility comprises one incubation unit and three RAS systems to grow fish to the smolt stage. The facility is designed to run four batches per year, with an expected smolt output of around 4 million at 100g each.

“We are happy to have this system in operation, which consists of core AKVA group technology, and it seems to be running extremely well. The systems have been performing excellently, and the growth has been really good,” said Hallgrímur Steinsson, CTO of Laxey.

The incubation unit was started in November 2023, followed by the completion of the start-feeding system RAS01 in December 2023. Feeding in RAS01 began in February 2024, with the installation of RAS02 and RAS03 following soon after. Significant parallel work has been conducted throughout, with Laxey consistently staying ahead of AKVA group to ensure a smooth construction and installation phase.

“Great teamwork has been essential, and we are proud to have contributed to the development, managing to complete it within the agreed time schedule from the start of the project,” said Mads Skøtt, Project Manager at AKVA.

When the smolt from the RAS reach the size of 100g they will be transferred to a post-smolt system using borehole saltwater coming from 30-metre deep holes. The post-smolt system consist of six fish tanks each of 18 metres diameter and a volume of 900 cubic metres, and is currently at the end of the construction phase.

When the smolt in this system has reached the post-smolt stage at around 500 gram they will be moved into Grow-out modules for final grow-out to market size of 5-6 kg.

A total of six grow-out modules will be built, each having eight fish tanks with a diameter of 28 metres and a volume of 5,000 cubic metres – giving a total rearing capacity of 40,000 cubic metres for each module. The first grow-out module is currently under construction to be ready for post-smolt stocking by mid-2025.

Following the completion of the smolt RAS, AKVA’s involvement has continued in the design and construction for the smolt re-use system and the first grow-out module. Responsibilities include quality checking Laxey’s engineering and design choices, standalone component delivery, and the mechanical and electrical installation of process equipment, along with the commissioning of sub-systems.

Laxey said it chose AKVA due to proven expertise in engineering and design, ability to deliver high-quality standalone components, and efficient handling of mechanical and electrical installations.

”This decision follows the success of our previous collaboration on the hatchery project, where a strong mutual interest to continue working together on the grow-out phase was established,” said Steinsson.

“With the smolt RAS now in operation, we are pleased to continue the excellent collaboration with AKVA group. We expect to expand AKVA group’s responsibilities and look forward to many more years of working closely together on this massive land-based project,” said acting chairman of Laxey’s board, Lárus Ásgeirsson.

The project goal is to produce 32,000 tonnes of large salmon by 2031. Currently, the grow-out module 1 for approximately 5,300 tonnes per year is under construction. Funding for module 2 is expected to be in place by the end of 2024, with execution starting in early 2025.

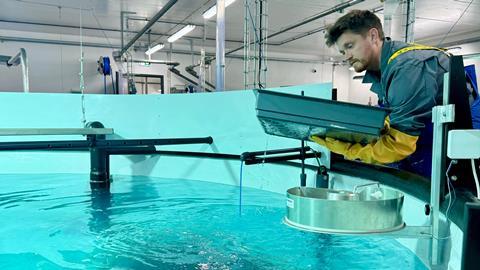

[Laxey AKVA.jpg] Caption: Transferring the second batch of fish from the hatchery to RAS 1